Glue Coating thickness – Thickness matters

“What is your glue coating thickness? ” is a very common question occurring in the conversation between clients and our sales reps. Coating thickness is so important that it is a crucial factor to check the performance of acrylic adhesive or polyurethane adhesive in the end products.

What is the coating thickness of adhesive?

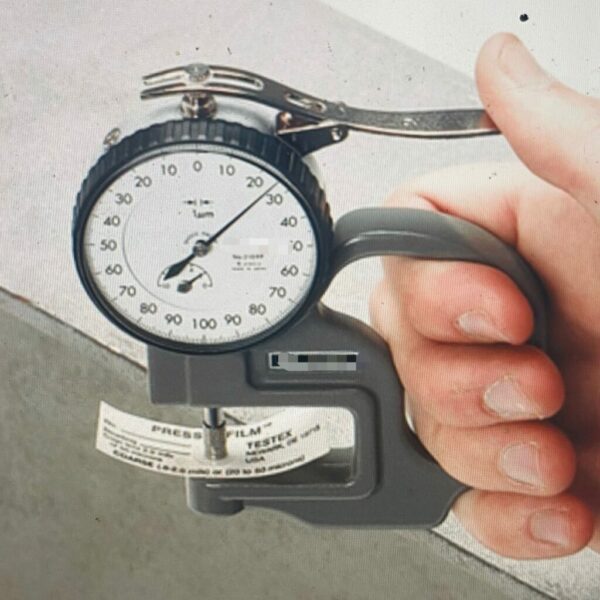

When it comes to coating thickness, that means the dry film thickness (DFT) consists of a single layer or multiple layers depending on the applications and production process. There are many tools designed for the measurement of thickness because dry film thickness is critical in many test standards such as ISO and ASTM.

Wet coating thickness

Wet coat thickness means film thickness before drying out the solvent. For the precision coating application, it doesn’t ensure that the coating is completely even, and again, the slight change of each batch of adhesive may be accumulated to huge inaccuracy.

If we can’t obtain a thickness gauge, another way to estimate dry film thickness is to use the solid content to time wet coating thickness (it comes from the coating gap).

For example, dry film thickness needs 15 µ and the solid content of the glue is 50%. Thus, the wet coating thickness ( coating gap) should be set up at 30µ to get 15 µ dry film thickness.

Material thickness also matters

On the other hand, the thickness of materials is another important but relatively easy issue. In short, the thicker the base material is the thicker the film thickness needs. Of course, the exact film thickness is also based on different films to meet the characteristics of each material. So, it’s also Chemix Guru’s capability of supplying a range of adhesives to meet each client’s requirements.

Dry coating thickness really matters

In all of our technical data sheets, the standard test such PTSC, etc., requires measuring the adhesion strength on PET board with a specific film thickness under a particular environment, and it’s very obvious to see how vital the dry coating thickness is. The importance of dry thickness is also the same in the onsite production process but proper modifications are subject to each project. So, please feel free to contact our sales rep to find out more about adhesives.

Coating thickness V.S Coating weight

In terms of coating thickness, that means dry thickness and the most common unit is µ (micrometer) or mil (equal to 25.4 µ). Some clients use coating weight such as g / m2 or oz. / in², but we think there may cause a little difference if applying precision coating industry such as slot die because viscosity and solid content of the acrylic adhesive are slightly varied among each production batch. Coating weight may work on the coating of PU adhesive but the tiny solid content change will affect the performance of the adhesion strength in the field of precision coating. Therefore, we suggest our clients should be able to measure the dry film thickness and ensure the quality of end products.