What is Solid content (SC)?

Solid content refers to the proportion or percentage of solid material present in a substance or mixture. It specifically denotes the amount of non-volatile components within a liquid, adhesive, coating, paint, or other materials that solidify or remain after the removal of solvents or volatiles.

In various industries such as adhesives, coatings, paints, and polymers, the solid part holds significance as it directly influences the material’s characteristics, performance, and application properties.

For instance, in adhesives or coatings, solid content determines factors like viscosity, drying time, film thickness, adhesion strength, and overall performance. Higher SC often leads to thicker coatings or stronger adhesive bonds but can also affect the material’s application properties.

Measuring non-volatile components is crucial in quality control, manufacturing processes, and formulation adjustments.

Testing Methods for Adhesives:

Equipment: hot air oven, precision balance

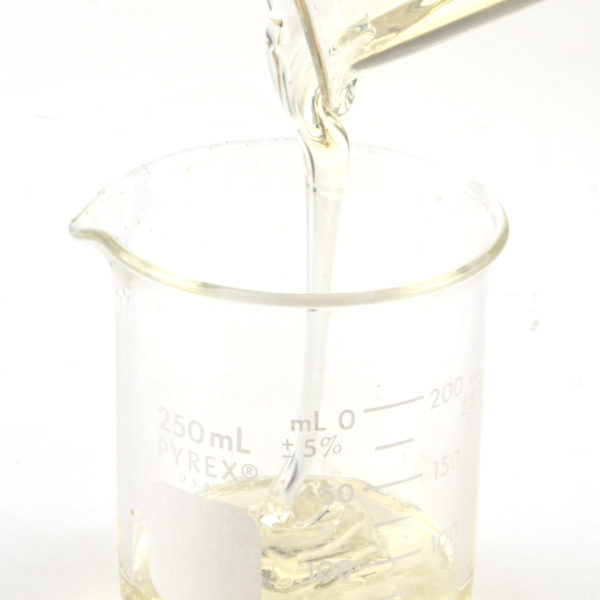

Take some samples in the container weighted and recorded. Put the samples in a hot air oven and dry them at a controlled temperature (150℃×15min.) to eliminate volatile components. The remaining weight indicates the non-volatile components.

- Solid Content (%) = (Dry Sample Weight / Wet Sample Weight) × 100%

- In the weight method, SC is typically calculated by measuring the weight of the dried sample (weight after removing all non-solid components) divided by the weight of the wet sample, then multiplied by 100 to obtain the percentage of SC.