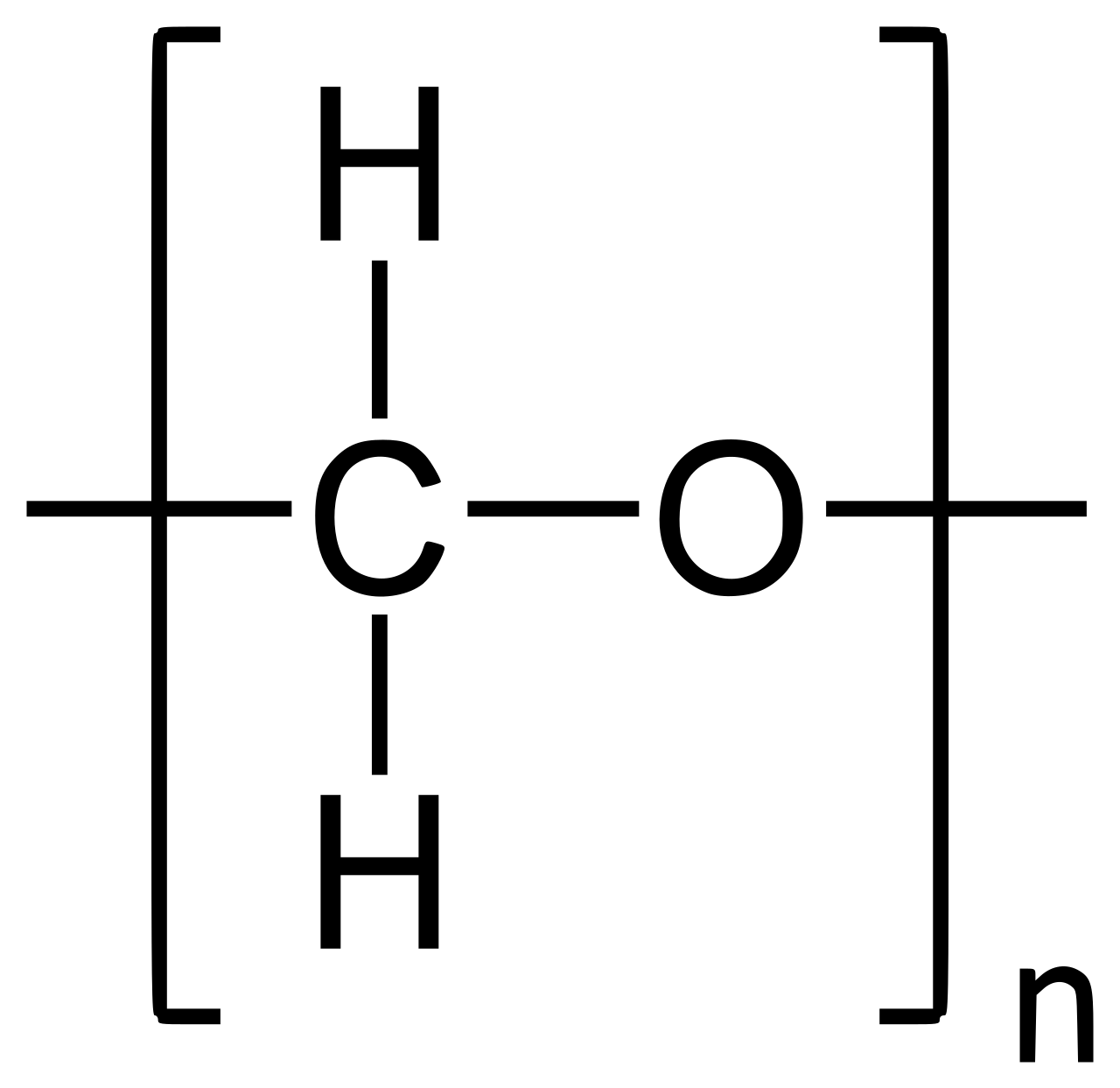

What is POM engineer plastic?

POM, or polyoxymethylene, is a type of engineering plastic that is known for its high stiffness, low friction, and excellent dimensional stability. It is also resistant to chemicals, moisture, and high temperatures, which makes it ideal for a wide range of industrial and commercial applications. In this article, we’ll explore the key properties and applications of POM engineer plastic.

Properties of POM Engineer Plastic

POM is a thermoplastic material that can be easily molded into various shapes and sizes. Some of the key properties of POM include the following:

- High stiffness and rigidity: it has a high modulus of elasticity, which means that it is very resistant to deformation and bending. This makes it ideal for applications that require high stiffness, such as gears, bearings, and other mechanical parts.

- Low friction and wear resistance: it has a low coefficient of friction, which means that it is ideal for applications that require smooth movements, such as sliding bearings, conveyor systems, and other machinery. It is also very resistant to wear and abrasion, which makes it ideal for use in gears and other moving parts.

- Excellent dimensional stability: it has very low water absorption and excellent dimensional stability, which means that it is resistant to changes in size and shape due to moisture or temperature variations. This makes it ideal for precision parts that require tight tolerances and consistent performance.

- Chemical and heat resistance: it is resistant to a wide range of chemicals, including solvents, fuels, and oils. It is also resistant to high temperatures, making it ideal for applications that require heat resistance, such as automotive and aerospace components.

Applications of POM Engineer Plastic

POM is used in a wide range of industrial and commercial applications, thanks to its excellent properties and versatility. Some of the most common applications of POM include:

- Automotive and aerospace components: it is used in a variety of automotive and aerospace components, including fuel system components, door handles, and gears. Its high stiffness and resistance to heat and chemicals make it ideal for these applications.

- Electrical and electronics components: it is used in a variety of electrical and electronics components, including connectors, switches, and relays. Its low friction and excellent dimensional stability make it ideal for these applications.

- Consumer goods: it is used in a variety of consumer goods, including pens, toys, and kitchen utensils. Its low friction and wear resistance make it ideal for these applications.

- Medical devices: it is used in a variety of medical devices, including surgical instruments and implantable devices. Its biocompatibility and resistance to chemicals make it ideal for these applications.

POM engineer plastic is a versatile material that offers excellent properties and performance for a wide range of industrial and commercial applications. Its high stiffness, low friction, and excellent dimensional stability make it ideal for precision parts and components that require consistent performance and durability. Whether you’re working in automotive, aerospace, electronics, or medical devices, POM is a material that can help you achieve your goals.

Need samples and want to know more about products please contact us.