PUR Adhesive for Fabric

Chemix Guru provides many options of PUR adhesives to meet customers’ requests. And our 100% solvent-free adhesive is the most important step to ensure our customers can catch up with the goal of sustainability.

Like our polyurethane laminating adhesives, our PUR for fabric adhesives also features lissome texture. Fabric-to-Fabric or Fabric-to-Film or Fabric-to-Foam laminating adhesive is a major application currently. However, customized service is also available to enable our customers to supply products with the best quality.

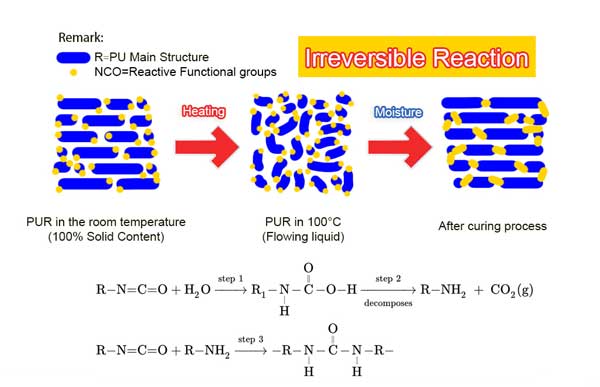

How does PUR adhesive work?

The reaction of PUR hot melt adhesives works with two components, the moisture in the air and the molecular polymers. After reacting, the bonding can have extraordinarily high adhesion and high degrees of temperature resistance, high flexibility at cold temperatures, and solvent resistance. However, the curing time will need longer than the current solvent-based adhesives to reach its designed strength. In addition, the storage of PUR adhesive is similar to polyurethane spray adhesive; they have to be packaged in moisture-proof containers.

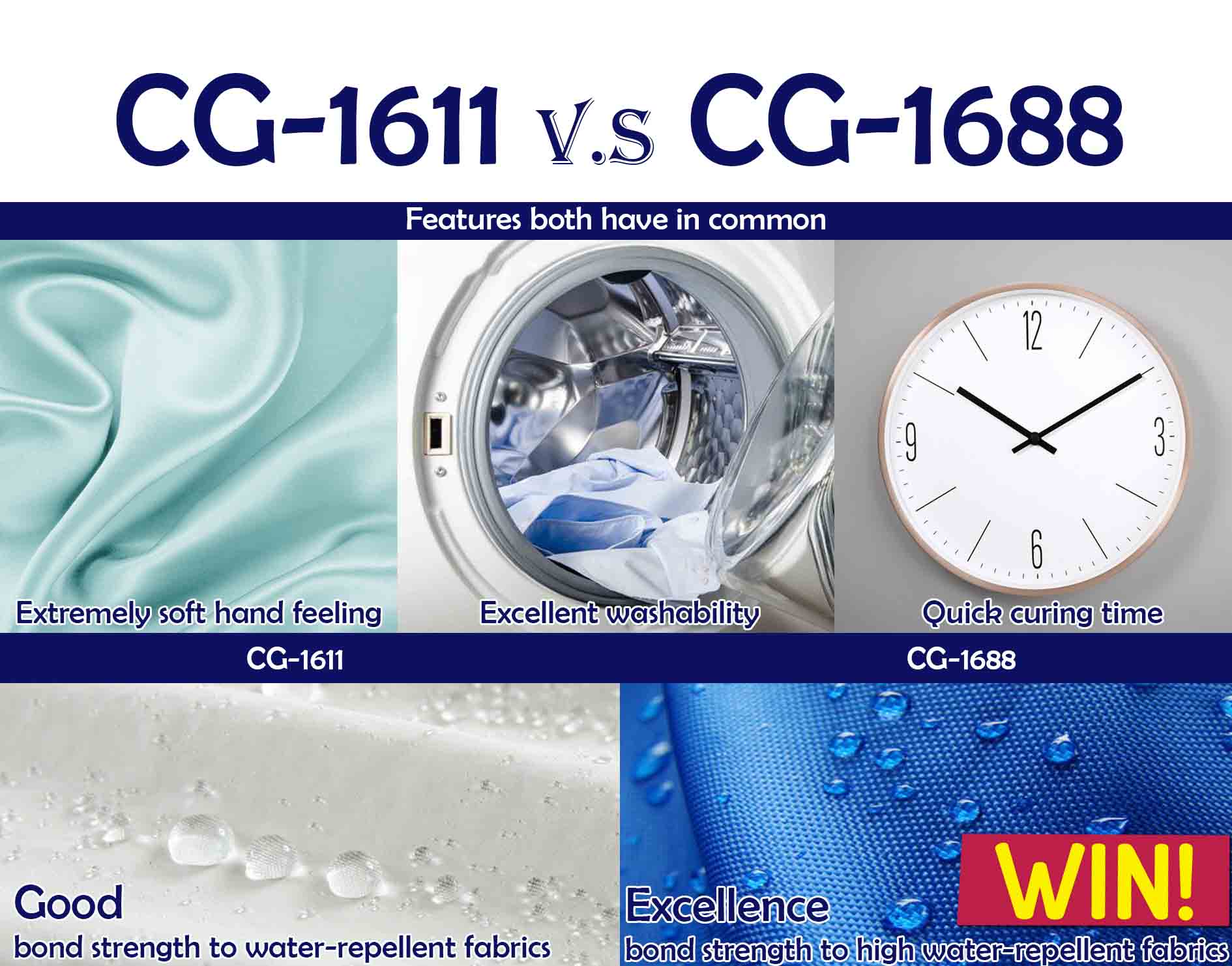

CG-1611

PUR Adhesive for fabric

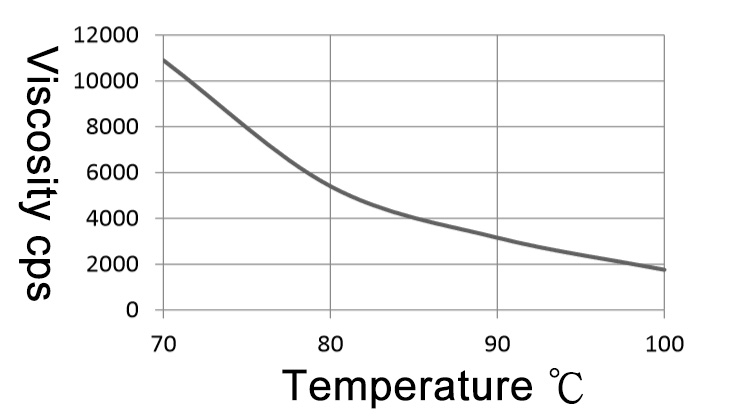

CG-1611 is a solvent-free hot melt PUR adhesive for fabric pretty well. It can be used in the lamination of normal polyester fabric, normal to water repellent treated polyester, TPU film, and PU film.

Characteristics

CG-1611 has the following characteristics:

- Strong adhesion to manifold fabric

- Soft hand feeling after fully cured

- Low processing temperature

- Direct coating without adding a cross-linkage agent

- High initial tack

- Good washing resistance

- 100 % Solid Content, Eco friendly

- With SGS report support

CG-1688

PUR Adhesive for fabric with High water repellent

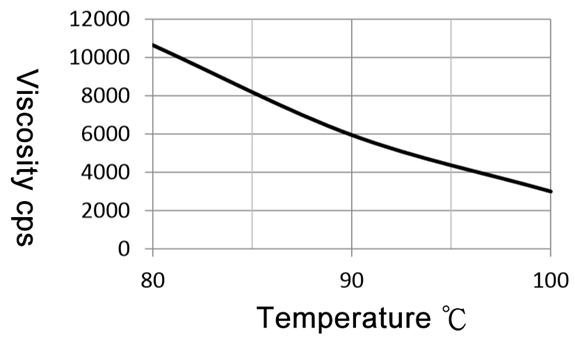

CG-1688 is a solvent-free hot melt adhesive for fabric with special treatment. It can be used in the lamination of normal fabric, high water repellent treated polyester, TPU film, and PU film

Characteristics

CG-1688 has the following characteristics:

- Strong adhesion to manifold fabric with high water repellent treat

- Quick curing, reach 60% strength in 4 hours (25°C)

- Low processing temperature

- Direct coating without adding a cross-linkage agent

- High initial tack

- Good washing resistance

- 100 % Solid Content, Eco friendly

- With SGS report support

Use PUR cleaner to clean up:

At the end of the day roller, cleaning is achieved by removing as much adhesive as possible from the roller and blade, purging with a small quantity (0.5kg) of PUR cleaner, solid plasticizer, run for 10 minutes at 100 – 120°C with a solid plasticizer for 3~4cycles, using a wire brush if necessary, drain and wipe clean. The resultant waste is mainly solid for easy disposal. The cured adhesive on the surface of the equipment needs a special solvent soaking overnight.

Request A Free Sample for trial production:

please contact us for a free sample of the adhesive, only a courier fee is charged.

Email: sales@chemixguru.com

Click the message icon on the lower right corner to send us your request.

Package: The regular package is the 18Kg or 20Kg barrel and 200Kg drum.

Related articles

What is the PUR adhesive?

PUR adhesive VS EVA hot melt adhesive

For more information about PUR please click here.

We require pu adhesive which will not melt 140 deg c temp

Thanks for you inquiry. Our colleague will reply you soon.

Do you have PUR glue suitable for food packaging material lamination. Eg, polyester film/ PUR/ Alu foil/ PUR / low density polyethelene for biscuits packaging.

Hi

I have required pu film for cloth to cloth bonding

After bonding a single drop of water 💧 not dropping from fabric our fabric nylon/polyester/viscous so you have any of these please get me email with literature

Thanking you ,

Jaspi chemicals

Paresh panwala

9825304446

India 🇮🇳

looking for PU Dispersion for bonding Fabric to Eva/TPR/Nylon sheet. Besides Moisture cure PU Adhesive for Re bonded Foam application. Please inform

Sandeep Ghosh

+917814208359

Yo porque no puedo, si quieres por cam, chat oalgo te abro}